It’s all fun and games until someone loses an eye. Or an axle. Or a 24-tooth crown gear. Or all of them in one sitting.

That was the challenge we faced here at Mid-Continent Public Library as we planned to make LEGO WeDo kits available for programs at our 31 branches. How do you circulate 40 kits throughout the system without losing most of the pieces — and your mind?

Plan ahead (and keep it simple)

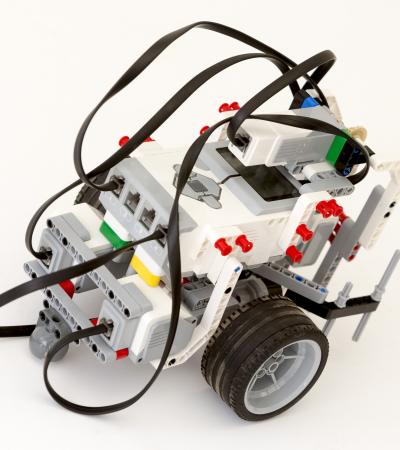

LEGO WeDo Construction Sets offer kids aged 7 and older the chance to build 12 robotic projects, which they can then program to move using a computer, LEGO software and simple drag-and-drop coding commands.

Once we ruled out just letting the kids stare at the box for an hour, we went to work figuring out how to structure a program that would be fun for the kids and easy for library staff to manage.

As any parent who has helped put together even the simplest build knows, LEGOs can be hard to wrangle. So many pieces are small and look like so many others. LEGOs also have the uncanny ability to roll, bounce, spill and then blend in with their surroundings. They’re the ninjas of the toy world.

Each kit has 158 pieces, and each project uses about half of those. So our first decision was to offer just one project per programming season and send out the kits with only the pieces needed to build that project. Branches could order a set of eight kits to accommodate up to 16 kids working in pairs.

For our first project we chose the Hungry Alligator. To set up the kits, we pulled out all 66 pieces needed for the project and put all the rest in cold storage.

The card is the key

The next challenge was making it as easy as possible for our branch staff to account for all the pieces that went with each kit.

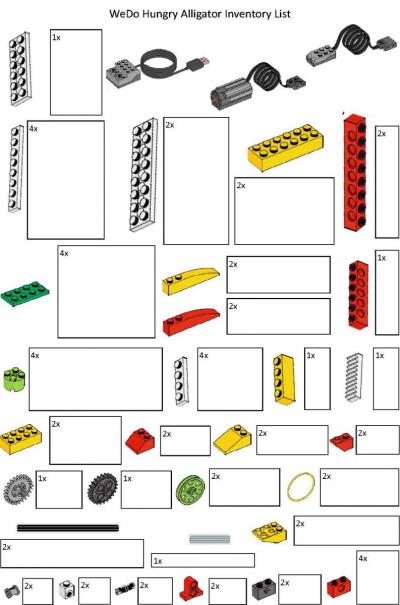

The solution was creating a 11-by-17-inch laminated card with an illustration of each piece in the project. Next to the illustration is a box with the number of that particular piece in the project. As the kids disassemble their alligators, they can put the pieces on the card and make sure they haven’t lost a piece. When kids are done filling out their cards, the presenters can check each team’s, make sure the kit is complete, and carefully tip the pieces into the container.

I was encouraged that the card idea might work when our building custodian walked by as I was using one to assemble the kits. He remarked that when he was in the Army, they issued mats similar to our cards to help new recruits disassemble their rifles. While LEGOs aren’t M16s, it felt good to think we were planning this program with military precision.

A success

When piloting the program with a group of kids over winter break, our plan seemed to work out, for the most part. The kids had fun building and programming their snapping robotic alligators, and we didn’t overly stress about keeping it all together.

In the end, the kids really took to using the cards to clean up and make sure they were returning all the pieces. The only casualties were two green rubber belts, stretched beyond their limits in the service of STEM education.

Oh well. You can’t plan for everything.